How movement affects your static alignment

Whenever the vehicle moves forward, the friction of the tyres on the road will place a load on all the steering and suspension arms. This load will deflect the suspension bushes, therefore altering the static wheel alignment angles. The age and construction of these bushes will determine how much deflection is present.

Factory rubber bushes will usually allow quite a bit of deflection, urethane bushes will permit minimal deflection, and spherical bearings or rod ends will suffer no deflection when used in the correct plane. Any deflection has a huge impact on toe. Depending on the location of the steering gear (either in front of the front axle or behind the front axle) it will cause either toe-in or toe-out and, at the same time, have a very minimal effect on camber and caster. This change in toe can be counteracted by reducing the amount of deflection in the bushes, and running a small amount of either toe-in or toe-out when aligning the vehicle.

Suspension compression and rebound has an impact on all the angles, however, the most notable one again is toe. This impact is known as bump steer, and is possibly the most dangerous effect of all. Its name is derived from what happens when you hit a bump. If your vehicle doesn’t have the correct geometry or has badly worn suspension components, the vehicle will steer itself either to the left or the right.

There are many factors that affect bump steer: Ackerman angle, roll centre, steering rack position, bush deflection or worn components. The vehicle’s roll centre has a large impact mainly because the roll centre is dictated by a line drawn through the lower inner pivot and the lower ball joint in strut-style suspension systems. Generally the lower control arm and the steering arm should be parallel to each other, and roughly parallel to the ground. If they are pointing upward excessively at the ball joint end of the arm, you will experience some form of bump steer.

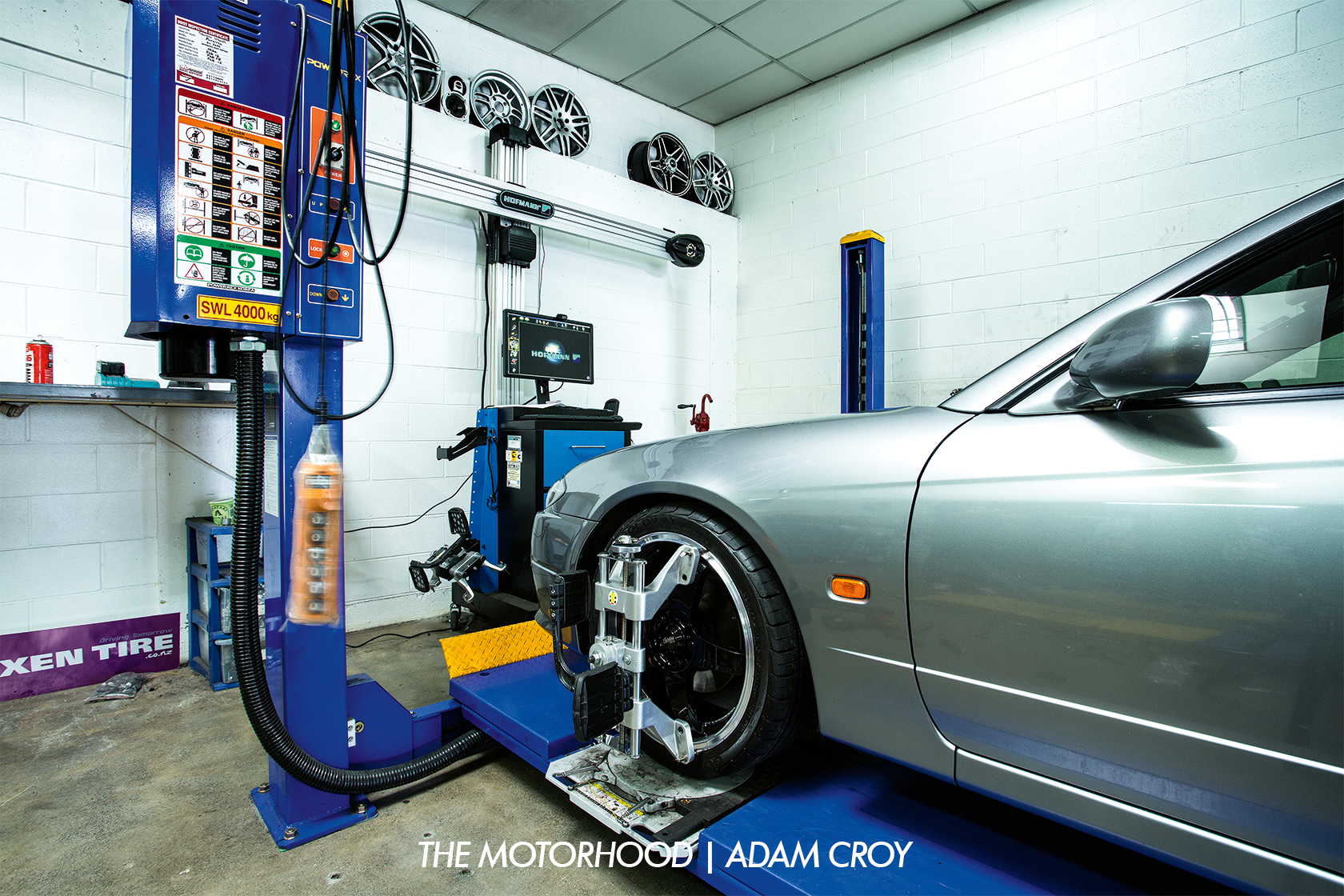

Adjusting the roll centre can be costly in most modern vehicles — it normally involves custom-made ball joints and tie rod ends, assuming there is nothing available in the aftermarket industry already. You will have to determine the correct amount of adjustment yourself, which is best done with access to a wheel alignment machine so the changes you make can be identified instantly. Thankfully, if you drive and old school rear-wheel drive car with Chapman front struts it’s as simple as purchasing some roll centre spacers, or RCAs as they are more commonly known. Adjusting the location of the steering rack on the other hand is far more involved, and will usually mean some form of cutting and welding of the cross member. Remember this is the main mounting point for the most important part of the steering, and failure to design and fabricate something of a very high structural standard will no doubt result in injury or death.

Ackerman angle

So what is it and why do we need it? This angle controls what is called toe-out on turns. When a vehicle turns through a circle the inside wheel needs to turn a little bit tighter than the outside wheel. It is only a little bit tighter though, if you measured the difference at 20 degrees of steering lock it is only two degrees. If you have zero Ackerman at the same 20 degrees of lock, both the wheels have turned the exact same amount.

Zero Ackerman can induce understeer, leave the vehicle feeling unresponsive, and will increase tyre wear. Ackerman angle adjustment is a bit of a hot topic at the moment, especially in drift circles. I have found through development that retaining some Ackerman in a drift car will provide a lot more response during switching. Adjusting Ackerman angle is easy in some cars and almost not worth it in others. Old rear-wheel drive vehicles have separate Ackerman arms, so some manufacturers offer aftermarket Ackerman arms, however, in most modern vehicles adjustment requires a full redesign of the hub.

Body roll has the biggest effect on just about all the angles, the main one being camber. The style of suspension in the vehicle will determine how body roll affects camber. As mentioned in the previous article, camber is used to maintain tyre contact while cornering. A Chapman/Macpherson strut style suspension doesn’t respond well to body roll.

When the body rolls camber will reduce on one side and increase on the other. Unfortunately the side of the vehicle where camber decreases is the outside wheel. A loaded wheel will provide maximum traction when it is perpendicular to the ground, so a loss of camber will reduce traction. This cannot be changed unless you convert from strut-style suspension to dual control arm suspension.

So to counteract this loss of camber a certain amount of static negative camber is required, and the amount of negative camber will depend on the intended use of the vehicle and on the style of suspension system. It can get as far as minus five or minus six degrees in dedicated track cars, however, the use of slick tyres with reinforced sidewalls and aggressive suspension packages makes this possible.

In a dual control arm suspension system you actually gain camber on the outside wheel during body roll. This is because the top steering axis pivot is at the end of the upper control arm. This allows the steering pivot to change its position in a vertical axis during suspension travel. Having this upper control arm shorter than the lower control arm causes the loaded wheel to become more negative during body roll, which makes the wheel/tyre more perpendicular to the ground, which equals more grip. This also means less static negative camber is required.

Adjusting camber is achieved many ways, whether it’s via camber plates, adjustable control arms or eccentric bushes. You can find out how much camber you need by using an infrared temp gun or tyre pyrometer. Just go to the track and run some laps, check your tyre temperatures on the inside, centre and outside edges and the closer these three temps are, the closer you are to having the right camber. Stay consistent with number of laps, driving style, tyre pressure, tyre brand and amount of camber adjustment, and you will soon find the sweet spot. Don’t forget any camber adjustment will change your toe setting dramatically, so this will also need to be adjusted. So now we know what happens when the vehicle and suspension is in motion and how it affects the static wheel alignment, let’s have a look at what a general track wheel alignment set-up would be.

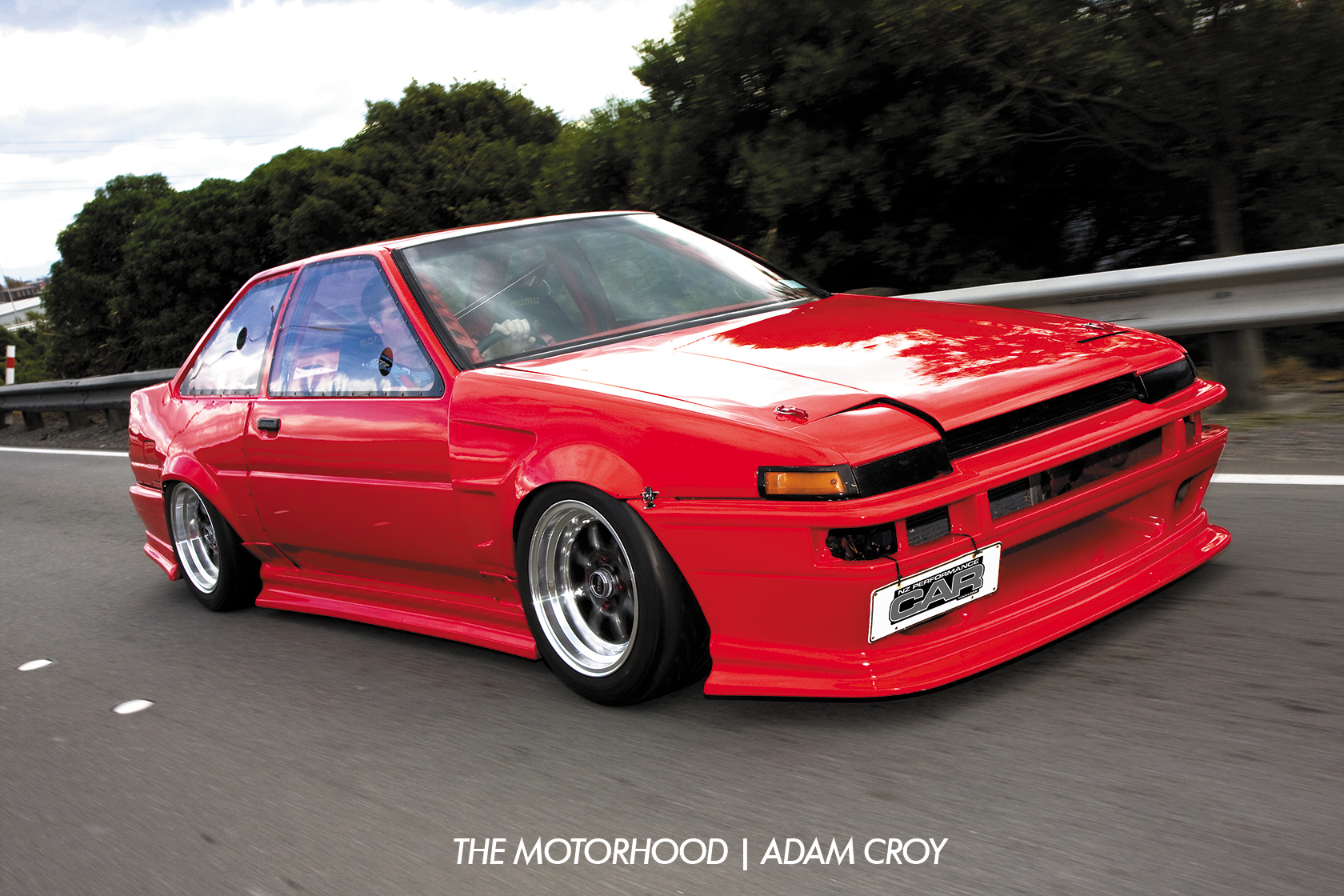

First we will look at a Chapman/Macpherson strut vehicle, let’s use a Toyota AE86 or any RWD vehicle on a similar platform.

FRONT

- Camber for this set-up will vary depending on suspension package, driver ability and type of tyre used, but will generally fall between minus 2.5 to minus four degrees.

- Caster will generally be as far positive as it can get. This is only limited by tyre clearance, you will probably get anywhere from seven to nine degrees.

- Ackerman should be around one degree more on the inside wheel at 20 degrees lock, but the factory two degrees is fine.

- RCA or roll centre adjustment will make a huge difference. General rule of thumb is that if your vehicle is 51mm lower than standard, use a 51mm RCA.

- SAI or steering axis inclination should be even left to right, if it’s not it’s a good sign there is something bent.

- A small amount of toe-out will give really good turn-in, but if you go too far it will be unstable at speed and could induce understeer. This measurement will mainly come down to how you want the vehicle feel, just like camber you should do some testing.

REAR

Being a live-axle rear end there is no adjustment other than lateral location via Panhard rod, this should be adjusted so the diff is centred in relation to the chassis. In a later-model RWD vehicle with multi-link front and rear suspension like a Silvia, Skyline or RX-7, it doesn’t really change too much. FRONT

- Camber will still be around minus two to minus three degrees

- Caster will be as much as your clearances will allow, which can be up to +11 degrees.

- Ackerman is the same, one degree more on the inside wheel at 20 degrees lock, but the factory two degrees is fine.

- Roll centre adjustment is difficult and only attacked if all other options have been exhausted.

- SAI should be even.

- A small amount of toe-out, less than in an old-school car, is acceptable depending on your personal preferences. Some toe-in may be required depending on the steering rack location of the car in question.

REAR

- Camber will vary depending what style of racing you are doing, anywhere from 0 to minus two degrees.

- Toe will have a huge impact on grip. This one takes a lot of testing, and there is no real general setting.

RACE CAR ALIGNMENT FOR MY STREET CAR?

Running a full race-style set-up on the street has no real benefit, and more than likely your car is going to drive badly and be illegal. A lot of the adjustment components like camber plates and adjustable arms may require a cert, and relocation of the steering rack or custom roll centre components may require proof of concept and or structural testing prior to getting a cert. You can still get the same benefits without going really aggressive. Find a good wheel alignment technician who is willing to work with you to find the best set-up, do some testing, and find what works for you.

Words: Gareth Court