“While LH Toranas are awesome cars, their biggest let-down is their steering, but now there’s an easy, locally produced solution to the problem”

If you’ve ever got behind the wheel of an LH Torana, you’ll know just how much fun they can be to drive. Like many cars of the era, though, the lack of power steering can leave you struggling to perform the simplest of low-speed driving tasks, like parking or U-turning.

Auckland-based steering specialists PG Hydraulics have been well aware of this issue for some time now, and have had customers from both New Zealand and Australia coming to them looking for a solution.

While they could have easily supplied a set-up that required the factory subframe or chassis to be cut, or engine mounts to be relocated, that was never an option for PG’s Managing Director Phil Game. Knowing full well just how collectible the cars are, especially genuine SLR5000s, Phil set about designing a set-up that could easily be bolted in and out without the need for any irreversible fabrication. Better still, the solution that he’s designed can easily be fitted at home over the period of about half a day!

Having been in the steering game for 30-odd years now, Phil’s been involved with converting many non–power-steer cars to power steer, as well as converting cars to rack-and-pinion, and to right-hand drive amongst other projects. So when it came time to start the Torana system, he knew exactly the rack to base the kit off — and that was a rack from a particular Subaru WRX model.

The Subaru racks are chosen due to their compact design and quality internals. However, getting them to fit the Torana application was no small job due to the positioning required. As the racks needed to be moved to the left to allow the pinion to fit through the small gap between the engine mount, chassis and cross member, the whole rack ends up off-centre in geometry. To correct this, PG devised a way to wind the rack bar out to the right to correct it. With a steering stop fitted, it ends up with the same amount of travel to the right as factory. The left-hand end is then shortened, as is the centre of the rack, before it’s all slid back together to get the joints into the correct position.

The result is a rack essentially 30mm shorter than stock, with the correct geometry, travel and stroke.

As Phil explains, “The important thing is getting all of the teeth to miss the seals in the housing. The other important part is that in a normal low-ratio Torana rack, they’re 3¾ turns lock-to-lock. In a high-ratio rack, like the L31 or L34, they’re only 3¼ turns lock-to-lock, but with the same turning circle, so we have to work around this, too.” The outcome is that the kits have been set up to offer three turns lock-to-lock.

While the racks are apart for machining, PG takes the opportunity to fit new bearings and seals, essentially making them a brand-new item. At the same time they’re fitted with new rack ends, and are plated so they look the part as well.

You can see the progress here as the original valve body (right) was first machined down to fit into the narrow space required (centre), before a full custom item was produced (left), shifting the port positions for optimal hose position.

“New ductile iron valve bodies are used, as it’s a high-strength material that’s good for taking high-shock loads and is long-lasting under pressure situations such as this,” Phil reveals. “We could have made the pinion housings out of aluminium, but the Teflon rings will eventually wear grooves in it, so if a person uses the vehicle regularly, especially in hot and cold environments, they could end up with valve body issues. The ductile iron has eliminated that and will mean that the racks will last for a couple of hundred thousand kilometres.”

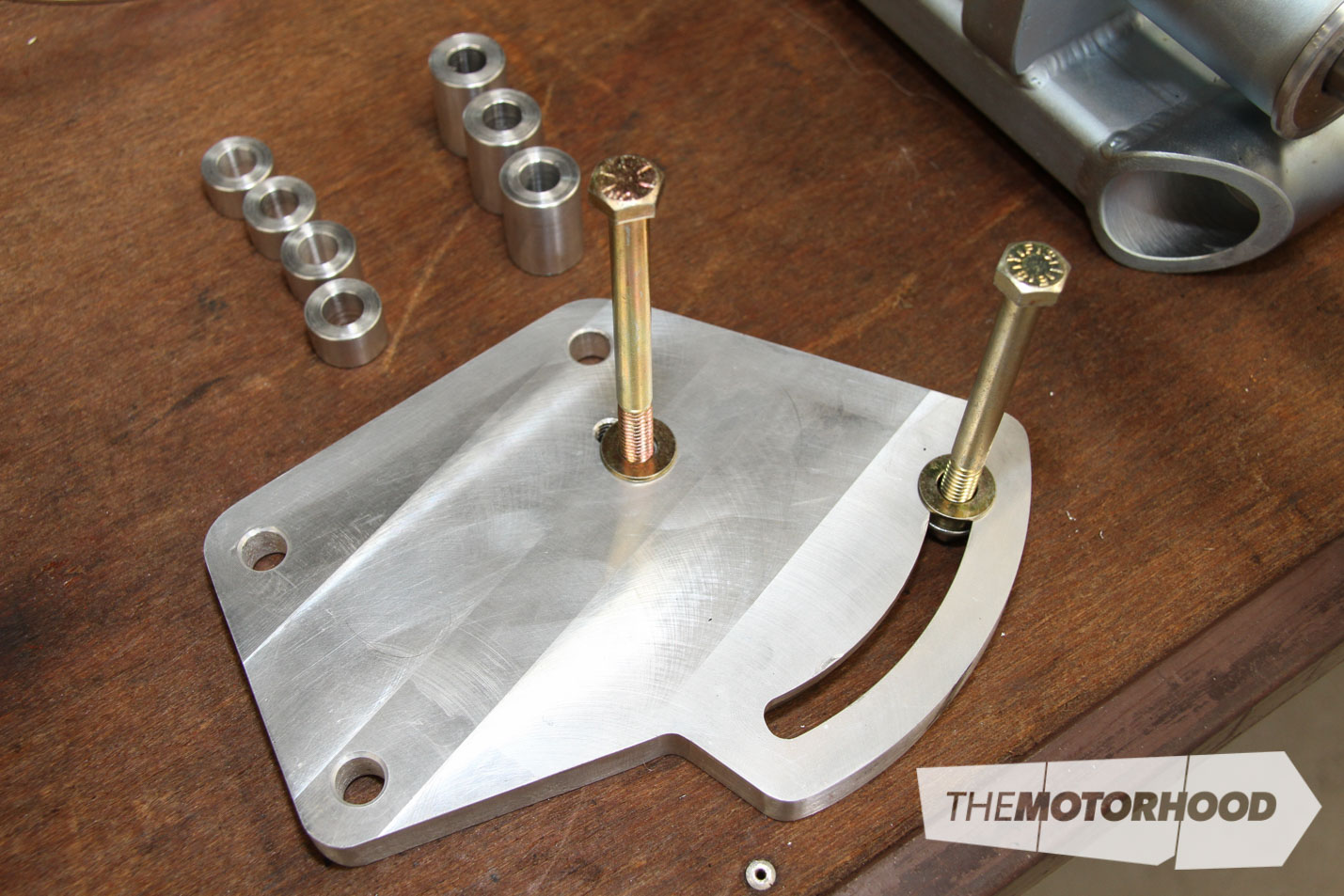

Both left- and right-hand pump mounts have been created, due to the variances in the vehicles' engines. When purchasing a kit, simply specify which side you need, and it will be supplied.

All aspects of the rack are made in-house, while the pump PG supply as part of the kit is an American-made aftermarket race car–type pump from KRC. The advantages of the KRC pumps are that pressure can be adjusted to suit each individual driver’s preferences.

“This particular pump is the same as what we’ve been using on all of the V8 SuperTourers. We’ve been selling them for seven years and have never had an issue with them,” Phil mentions.

While the first of the kits has been made entirely in-house at PG, Phil’s well aware that if the demand continues he may need to outsource some of the fabrication. However, after investing plenty of time into the development of the kit, Phil’s confident in what he’s created, and has in fact held off promoting the kits until he was happy that supply would be able to keep up with demand. “At the end of the day, it’s about making sure we’ve got the parts and a back-up service should something go wrong,” says Phil.

With the kit mounted to a dummy subframe, it's easy to see just how tightly the valve body needs to fit, in order not to foul on anything.

“We’ve done so many different vehicles; at the moment we’re fitting power steering to a 1929 Studebaker of all things. The biggest thing with the Torana kit is making the rack fit the cross member without having to modify the cross member itself. That’s where the time and effort has gone,” he continues.

The short shaft extension, which comes as part of the kit, means the system is entirely bolt-in, bolt-out, with no fabrication or cutting required.

The result is a full bolt-in kit, that comes complete with rack, pump, hoses, shaft extension and all of the required mounting hardware, all of which can easily be fitted at home, or by the team at PG themselves.

The first vehicle to be fitted with the set-up is the genuine SLR5000 of Gary Mickley. Having grown up three hours away from Bathurst, Gary’s owned a bunch of old Holdens and Fords over the years, and was stoked to have recently purchased the car. Having driven modern cars though, he’d forgotten just how bad the steering was. “I can’t believe what we used to put up with! We grew up with it, but after driving something with power steering it’s hard to believe we actually did it,” he says of what the car was like prior to having PG fit the kit.

“I couldn’t park it, you’d be too embarrassed to. You’d have to be so careful due to the [lack of] lock. My son took it for a drive and came back saying, ‘Dad, I know why you’re getting power steering now’,” mentions Gary, who goes on to say, “I’d rather put up with it than have to cut the car up though.”

We were there as Gary first laid eyes on the completed vehicle, of which he said, “Man, that’s really nice. It looks like it belongs there; it looks like that’s how it came. What a job! If you didn’t know, you wouldn’t know. It’s that good that you’d be able to convince people that it was a factory option.” High praise indeed, coming from someone with such an immaculately presented vehicle.

But the big thing isn’t what the kit looks like, but how it transforms the way the car drives, and again, Gary couldn’t be happier. After pulling off a successful U-turn in a medium-sized street, he says with an ecstatic grin, “It never would have done that before in one turn. I’d have gone around the corner out of sight before turning around. They’ve adjusted it up to be perfect. Now even my daughter can drive it, whereas she couldn’t before.”

When asked about his thoughts on the price, he says, “I don’t mind paying for a job that’s well done, and this is way better than I ever thought it’d be. I knew they’d do a good job, but I’m blown away by it. Only real Torana people wouldn’t know that’s not a factory option.” Gary’s final statement of “It’s a 10 out of 10, you couldn’t ask for any better than that” says it all really!

It sounds to us like, regardless of the cost, it’s a small price to pay to make the car that you’ve always dreamed of owning into the car that you’ve always dreamed of driving.

This article was originally published in NZV8 Issue No. 101. You can pick up a print copy or a digital copy of the magazine below: