Words: Todd Wylie / John Mincham

“This 1967 Impala has run badly when cold for a long time, but when it started to run badly even when warm, the owner knew it was time to sort it. We tagged along to see what the problem was”

The owner of this 1967 Impala picked the car up locally, but un-VINed, around four years ago. With the body straight but tired, the first thing on the agenda was to get it painted up and looking as he wanted it to. Since the car seemed to run OK on purchase, no attention was paid to the 327ci small block at all besides a new set of ignition leads being fitted around 12 months ago.

The car’s always had issues starting when cold, taking plenty of cranking and assorted amounts of gas to fire into life. When it did start, it wouldn’t run on all cylinders and pumped out plenty of smoke. After a minute or so, it seemed to settle, but would still be reluctant to move for a while longer. Then, as soon as it was put into gear, the revs would drop and the car would stall.

Adding to these issues, when the driver put his foot down on the motorway or similar, the car seemed to severely over-fuel, but with the car being a cruiser, the owner lived with it, and chose to always drive it gingerly. But over time on the road, the over-fuelling became worse, as did a persistent exhaust leak from near the headers. It wasn’t until it continuously fouled plugs and required them to be cleaned before it’d even start that the decision was made to sort the problem out.

The owner laughs now that what he thought was a bad wheel balance last summer on the motorway was actually the motor running on seven cylinders ...

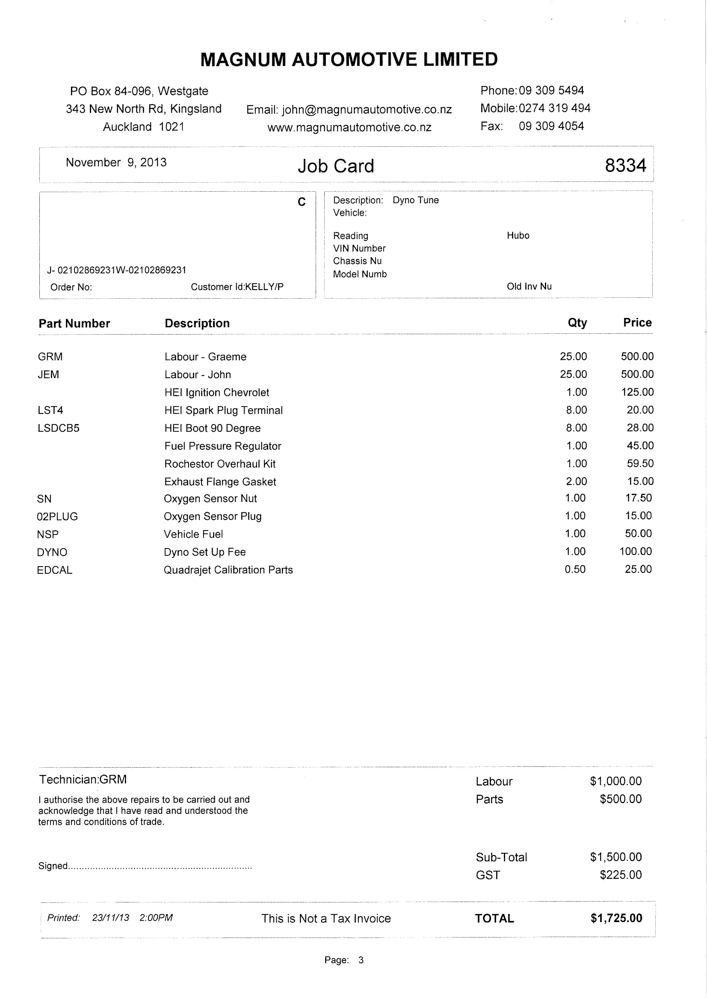

Magnum Automotive were called upon to get the car running as it should, as not only does Magnum work almost solely on older V8 vehicles, but its rolling-road Land and Sea dyno would allow the car to be tuned to its full potential.

Step one

The beginning of the whole process was to start the car first thing in the morning when the engine was cold to see what was going on. The car ran so incredibly badly that the Magnum team were surprised it was actually running at all.

Besides the serious amount of smoke coming out of the exhaust, it was also apparent the exhaust leak up front was a major one, and one that would require fixing before anything else. The reason being that if it were to be put onto the dyno, the dyno’s O2 sensor wouldn’t have been able to get a correct air/fuel ratio (AFR) reading.

The problem

From factory, the car was equipped with a valve just below the headers which was designed to close under deceleration to provide increased back-pressure. With an exhaust join both above and below the valve, there’s plenty of room for leaks, and that’s exactly where the problem was. With the flap itself long gone, but the shaft still in place, it soon became apparent that it was also leaking around the shaft seals.

The fix

With the valve assembly removed from the car, the shaft was taken out and the holes welded up. When reinstalled into the car, new gaskets were put in to replace the badly damaged originals. While it would have been possible to modify the exhaust and remove the valve completely, the owner was keen to spend as little as possible, so it was decided against.

With the car on the hoist, the Magnum team also installed an O2 bung into the front of the exhaust. Not only would this come in handy now, but also in the future if any further issues eventuate or if the owner decides to upgrade anything.

Step two

With the exhaust leak sorted, the car was strapped to the dyno and left to sit till the next morning where it could be run up, with an O2 sensor, fuel-pressure sensor, and timing light attached to record what was going on.

What was discovered was a whole host of issues. First of all, with the exhaust leak fixed, there was audible detonation and the ignition output was very poor, yet the points voltage was overly high. Fuel pressure was also on the high side for a Rochester carburettor, at 8.5psi, and the car was running too much timing at 37 degrees. Of course, the original problem of poor choke operation was also very apparent. The fuel pressure was causing float levels that were too high and flooding at idle. At full power, it was also running extremely rich, with a 10:1 AFR, which was what was causing the big clouds of black exhaust smoke when the throttle was pressed remotely hard.

The fixes

The detonation was actually an easy fix. As the owner hadn’t taken into account this particular 327 is a high-compression motor (10.1:1), the same as was used in the Camaro SS of the time, he’d been running the car on a mix of 91- and 95-octane fuel, though as a cruiser it had never been leaned on in any case. With the tank drained and a new tank full of 95 (Magnum recommended the owner use 98 where possible), the detonation was cured.

The solution for the ignition system was to replace the stock distributor with an aftermarket high-energy–ignition (HEI) item. The new ignition leads the owner had installed needed to have new ends fitted to match up, and at the same time the lead lengths were significantly shortened. The new distributor’s advance curve and vacuum-advance system were all tuned on the dyno, and the car now runs six-degrees base and 28-degrees total timing, which is right for the 10.1:1-compression motor.

While changing the fuel pump was an option to sort the fuel pressure, it was actually working well higher up in the rev range. So, the fix was to add an aftermarket adjustable pressure regulator between the pump and carb. With it adjusted to read a steady 4psi, it is now sufficient throughout the entire rev range.

With these issues sorted, the team could finally look at what the original issue was thought to be: the carb.

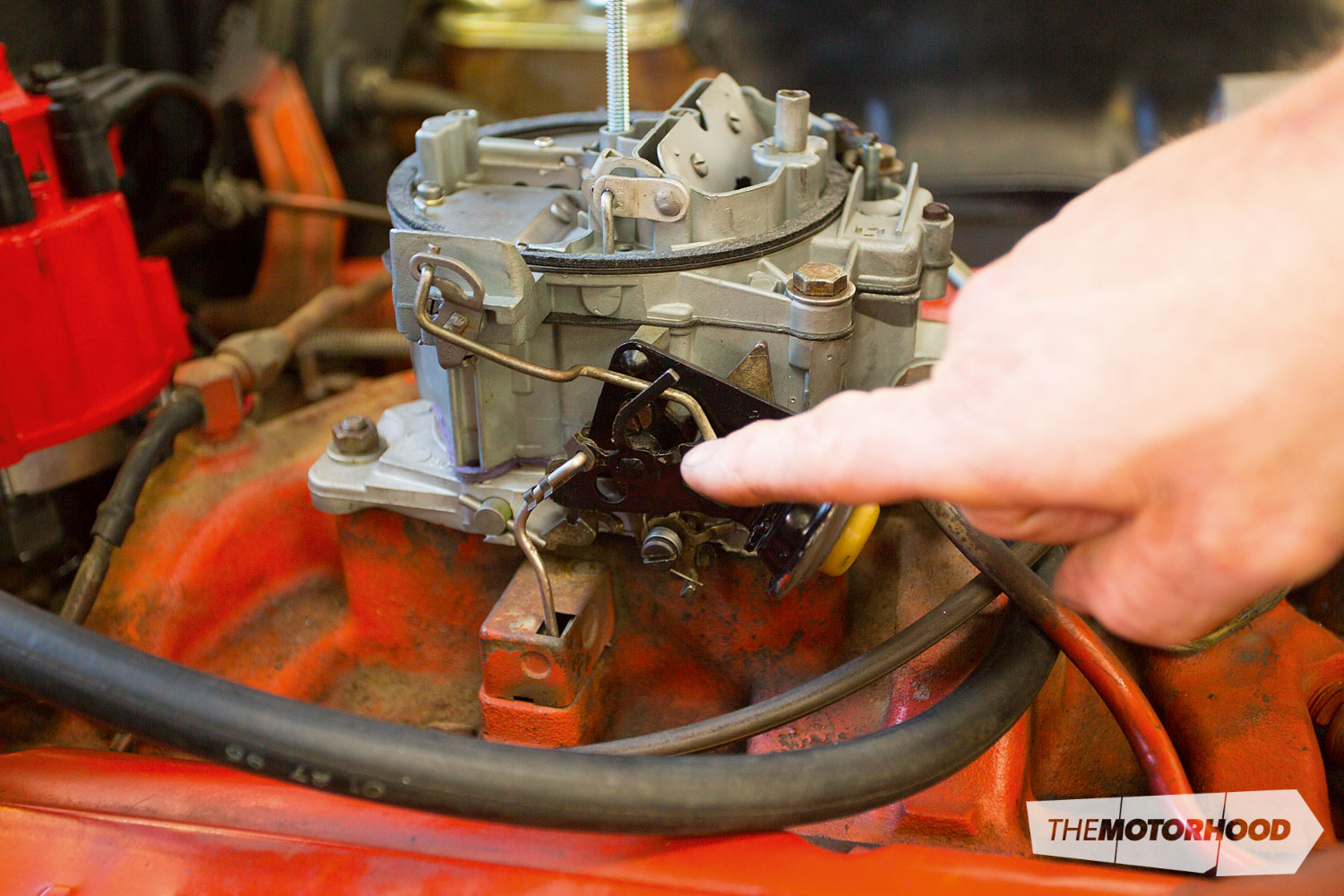

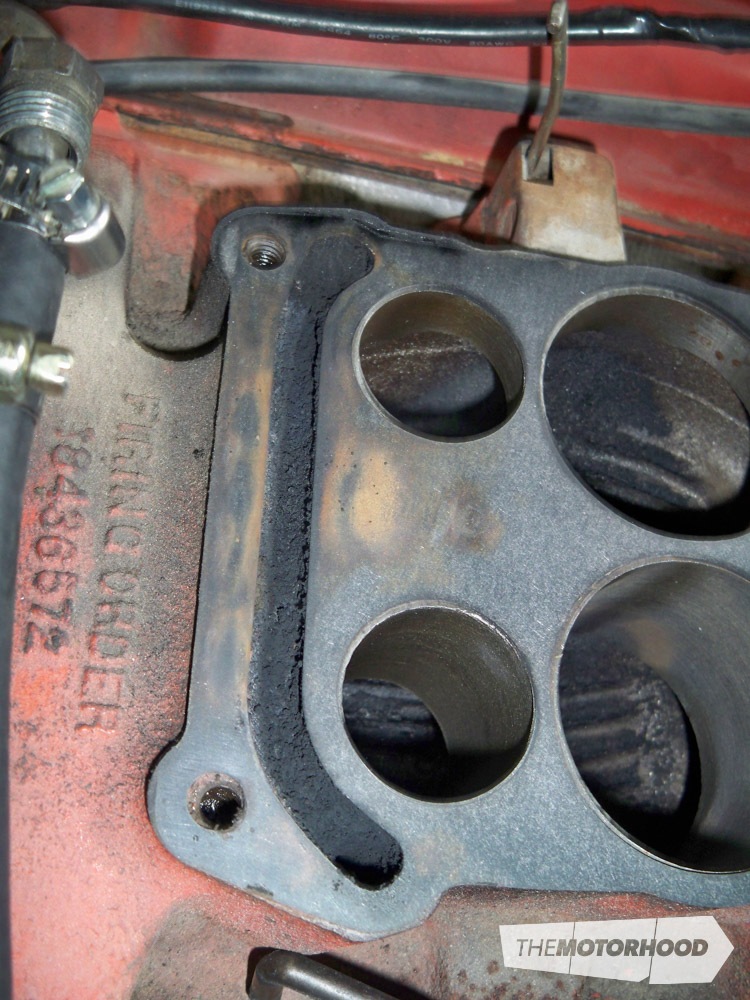

Looking like it had seen no love since the car was brand new, the first step was to remove it from the intake manifold, and give it a decent clean. The amount of black build-up in the balance tube gave an indication of how the rest of it was. A thorough inspection of the carb soon revealed that the base of it was warped, most likely caused by a combination of being bolted down too tightly, and someone screwing the air filter on too tight, which pulled the ends down and the centre upwards. With some careful tweaking, this was straightened out. The problem is a common one for these Rochester carbs, and when repairing them, great care is needed so as not to snap the base.

When reassembled with new gaskets (for which a kit is readily available), the car was once again cold-started. The choke operation in these carbs is controlled by a rod down the outside, and adjustment is by way of bending the rod to the correct position. The only way to get it perfect is by trial and error, and in this case a whole lot of previous experience of doing the exact same thing.

During inspection of the carb, it was noted that one secondary accelerating well tube was missing, with the only conclusion being that it’d most likely gone through the engine at some stage. The spare-parts bin was raided and a replacement tube installed.

With the carb refitted to the car, it was once again run up on the dyno, where the idle and primary circuits were tuned to operate correctly.

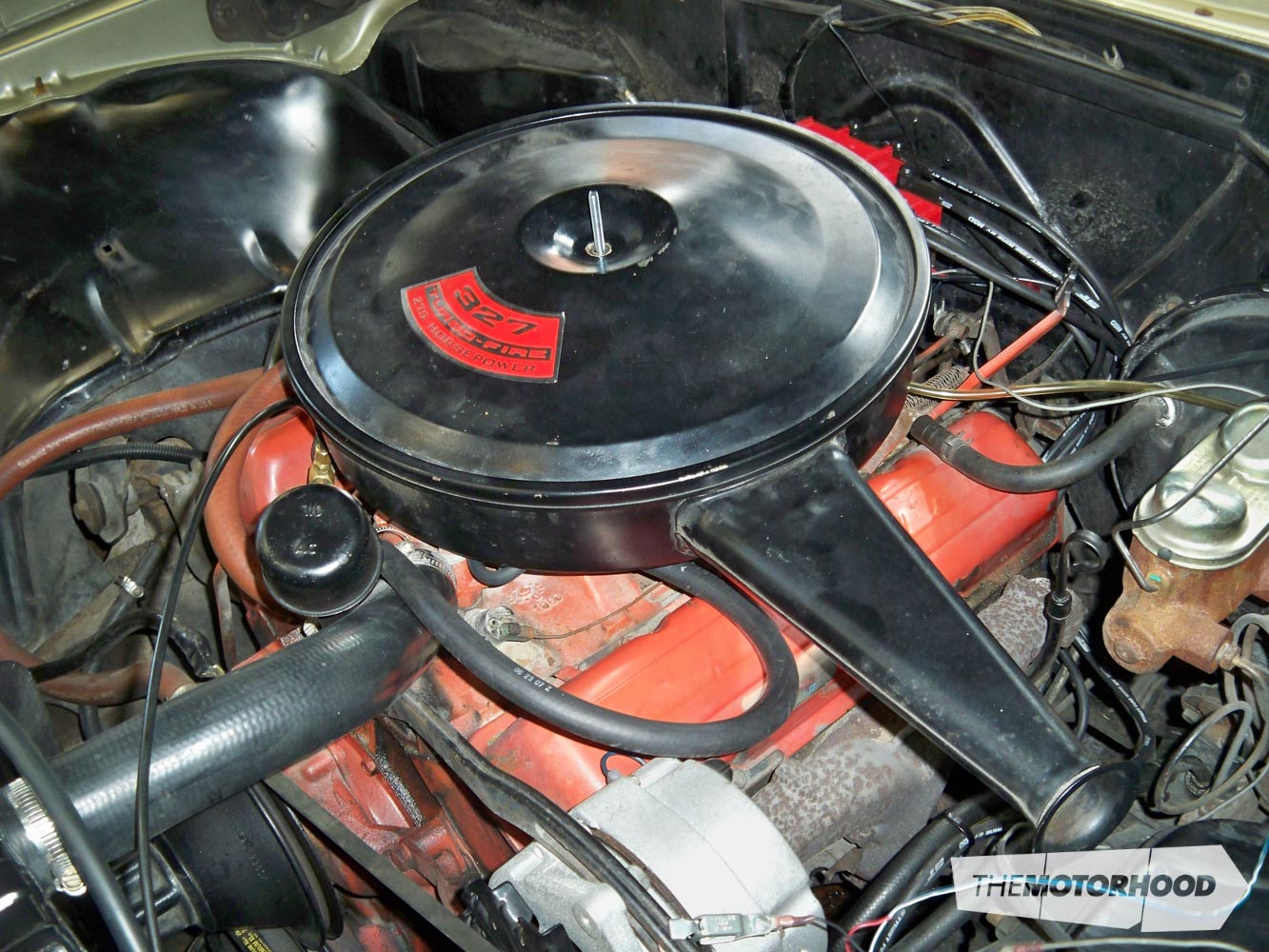

The secondary system required a little more massaging, as higher up in the rev range it still wanted to run rich. The solution to this was to fit an aftermarket air filter, which offered 360-degree filtration, as opposed to the stock air cleaner’s very small inlet (as seen above).

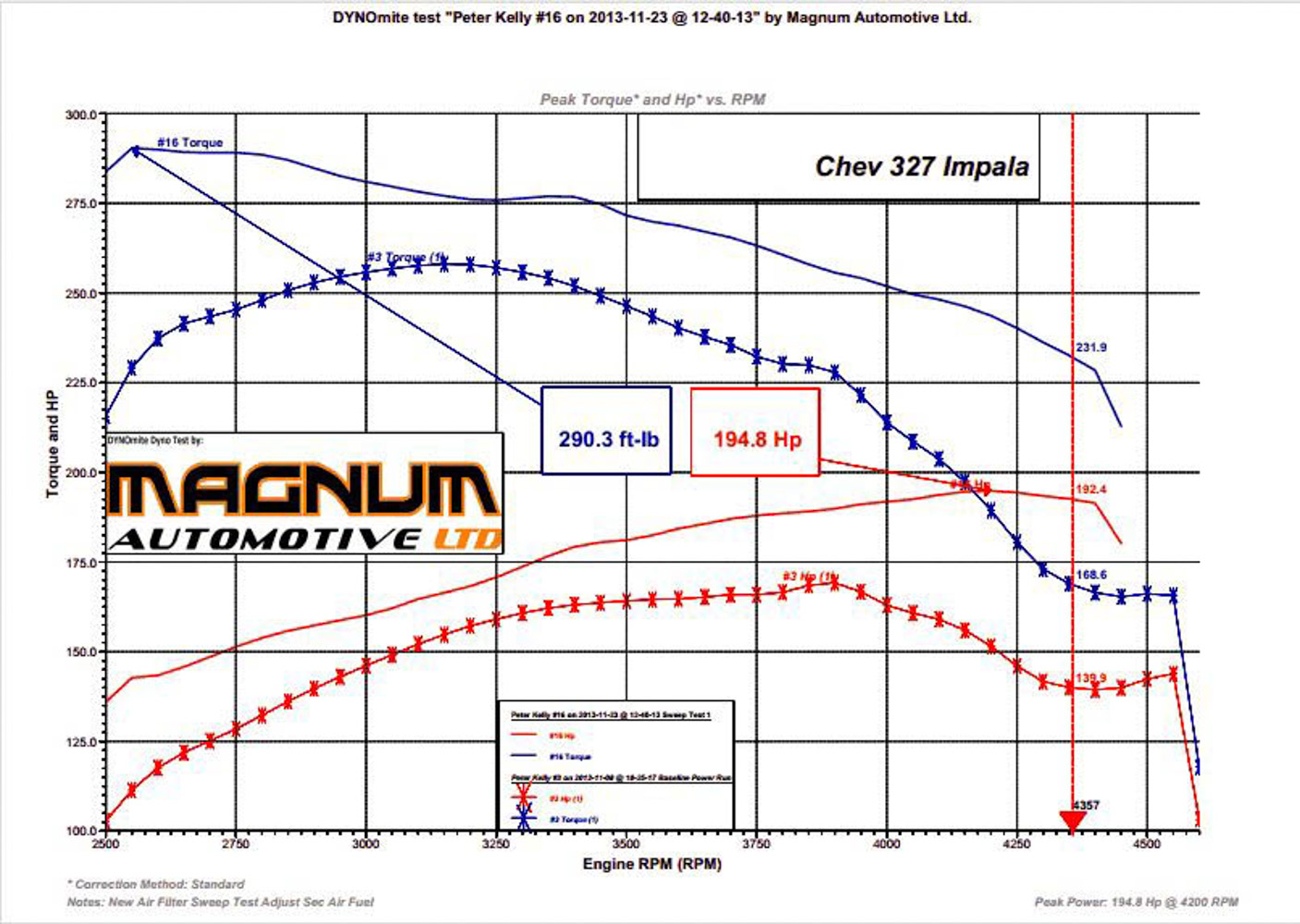

With the new filter fitted, not only was the AFR corrected, but the car now actually makes more power, with a peak figure of 194.8rwhp at 4200rpm. The big thing, though, is the massive increase in torque, with the maximum figure now 289ft·lb at 2600rpm, as opposed to the original peak of 257.8ft·lb.

Conclusion

In the words of the owner, the result of the work is a car that’s “no longer lazy in the way the power is delivered, the pedal feel is also completely different, much crisper.

“It’s still just a cruiser, but at least now I know it’s running well and I don’t have to worry about it dying while taking a bride to her wedding.”

And on the subject of the cost of the work, the owner said, “Like I said to Magnum, realistically, I’ve had to do very little to the car since I’ve had it, and it’s a given that things will need to be done. While it cost a bit, the truth is, my much more modern van has cost me way, way more, so in the grand scheme of things, it’s certainly money well spent.”

On cold-morning starts, he told us, “It still cranks over a little bit, as you’d expect, but fires up nice and crisply. I don’t have to sit there fighting it like I used to, trying to keep the revs up, as if it died, it wouldn’t want to start again.

“Not only does it now start nicely and run smoothly, but the trail of black smoke under heavy acceleration has now also disappeared.” Sounds like a great result all round!

Photos: John Mincham / Adam Croy