“How’s this for an old-school concept — no, not the car — the idea of our Concept Corner being thought up in house at NZV8?”

Before the monthly Concept Corner became a means for the owner of that issue’s cover car to explore the most mechanically outrageous depths of his or her mind, it was an in-house job.

I’ve never actually done a Concept Corner, but, since Aaron Beck gave us his awesome concept sketches — which you can see on pages 34-37 — I was given the chance. Here goes! Since I love gassers and have a bit of a soft spot for old Holdens, let’s look into a street-legal Holden EH panel-van gasser.

The whole front end could effectively be chopped off to make way for a custom-fabricated front clip. That would tie into a six-point roll cage and would not include any kick-up for the suspension mounting points. There would most certainly not be any sheet metal left for inner guards. The fenders, nose cone, and bonnet would be combined into a tilt front, mounted on a tube frame, and the lights would be kept functional.

A Moon tank would be fitted for looks, as it’s unlikely it could legally be used as a fuel-injection return tank — more on that soon.

The custom fabrication would allow mounting provisions for parallel leaf springs, Moroso 90/10 shocks, and a straight front axle — for the perfect ‘nosebleed’ stance. As much as I’d like to include front drum brakes, un-boosted Wilwood Superlite calipers and discs would probably be a more reasonable bet — although I’ve got no problem with drums out the back.

Wheels are make or break, so we’d chuck it on some 15x4½-inch ET Gasser 10-spokes up front. Out back, it’d have 15x10-inch widened steelies, painted matt red and wrapped in M&H 26.0x11.5x15 cheater slicks. The rear guards would also need to be radiused and tubbed, and the B-pillar would be moved back around five inches and the front doors extended to tidy up the side profile.

Since we’d be trying to keep the oily bits in the family, I’d opt for a narrowed Chev 12-bolt diff under the arse end, with ladder bars and double-adjustable coilovers. While I’d like a Holden 10-bolt Salisbury diff, the relative lack of aftermarket parts would deem that not to be a good idea. I’ve always found diffs with bolt-on cover plates a lot better looking than nine inch–type diffs, anyway.

Of course, it’d have to be a manual. No messing around here: Jerico straight-cut four-speed dogbox. Engine-wise, it’d have to be a high-revving naturally aspirated big block. I’m thinking maybe around 402ci, with forged high-compression pistons, solid-roller camshaft, and Kinsler or Hilborn eight-stack mechanical fuel injection, running on E85. Custom fenderwell headers would be a must; I’d have them HPC coated in white, and the four-into-one merge collectors pointed directly groundwards, much as an Ed Roth cartoon would depict. Ideally, this would have a V-band connection, allowing a detachable V-band elbow connecting it to a hidden exhaust system for street use.

Inside, a Moon tacho, Grant steering wheel, and Hurst shifter would be all taken for granted. We’d have a pair of vintage-style Kirkey low-back bucket seats, re-trimmed in quilted red vinyl — hey, it’s a gasser! — with matching door cards and flooring. This would extend to the rear, which would house the slightly recessed fuel cell, and be blocked off by a sheet of red-tinted Perspex. The side windows would also be red-tinted Perspex.

As much as I’d like the EH to be finished with a custom paint job, including lace painting, metal flake, pinstriping, and gold leaf, I’m too useless for any of that. Matt black is the flavour of the day, although I’m sure a nice candy-apple red finish could be applied to the gasser’s name — ‘EHLLBOUND’ — down the side. While we’re at it, let’s chuck some red tinting on the headlight lenses. Done and dusted. What do you reckon?

LVVTA’s view

Justin from the LVVTA says: While the gasser look is popular right now, don’t forget that an increase in a vehicle’s height will always make the car less stable; it’s simple physics — the higher it goes, the higher the centre of gravity will be, and the less inherently stable the car will be, particularly at higher speeds. That is why we’ve spent practically all of our adult lives lowering a car’s suspension! But I digress — the gasser look does appeal, in most cases, and so long as the handling can be maintained through a carefully thought out set-up, it is feasible.

The vehicle’s overall handling and drivability would need to be assessed by the Low Volume Vehicle (LVV) certifier — so properly calculated spring rates, correctly valved shock absorbers, well-designed and well-set-up suspension, an increased wheel track, quality tyres, and good sway bars would all help in keeping the vehicle’s handling characteristics as close as possible to those of the original unmodified vehicle.

Check out chapter 19 of the NZ Hobby Car Technical Manual (NZHCTM) so that you have a good understanding of what the certifier would need to check in relation to the vehicle’s suspension, steering, brakes, and handling when they’re road-testing the vehicle. Also bear in mind that the M&H tyres, while being DOT approved, may not be suitable for road use, so you’d need to check the tyre details carefully before committing your hard-earned cash to this purchase.

As you’re probably aware, the EH is a unitary construction type of vehicle, so, while grafting a new pair of chassis rails on the front shouldn’t be an issue, it’s likely that you’d need to add some strength to the integral chassis and floorpan, usually quite easily achieved by adding a pair of chassis stiffeners or chassis connectors that link the front and rear rails together, improving torsional rigidity. The roll-cage structure would also help with this, but you’d need to plan this carefully, as there are a few requirements, particularly relating to the ‘interior impact’ rules, which basically state that no part of the roll cage can be positioned within the head-strike ‘A-zone’, and that it must be padded when positioned adjacent to any A-zone. A rear seat can’t be fitted — which wouldn’t be a problem here, anyway — and, luckily, it’d be an ‘NA class’ goods van, as a roll cage couldn’t be fitted to the station wagon or sedan ‘MA class’ passenger version of the EH. Check out the Interior Equipment chapter of the NZHCTM for more details relating to roll-cage requirements, and also to see examples of interior zones.

In a vehicle like this, a roll cage can be dealt with in two ways:

Option 1

The roll structure would need to be approved under the rules of the New Zealand Drag Racing Association or MotorSport New Zealand and be covered by an LVV Authority Card — see NZHCTM, chapter 3, Authority Card Process, for details. If this were the preferred option, then full harness seat belts could also be approved for use provided the applicable requirements are met — but this might necessitate a change to your preference for Kirkey low-backs, so you’d need to check the appropriate rule book or talk to a tech inspector or scrutineer for more details.

Option 2

LVVTA doesn’t have ‘roll-over protection’ requirements, as these stem from international motorsport requirements, and it’s better for consistency if these requirements are administered by the applicable motorsport governing bodies. Therefore, if the vehicle would not be covered by an LVV Authority Card, the certifier would approve only two aspects of the roll cage or roll bar: (1) interior impact (head strike) and (2) seat-belt attachments. So, when a seat-belt anchorage is being attached to a roll-over structure that is not going to be approved by the motorsport body, that structure needs to meet the requirements for a ‘seat-belt support frame’ (refer to section 14.54 of the NZHCTM).

A Moon fuel tank can be used and can be fitted in front of the front-axle centre line provided it is adequately protected by being located within the confines of the body or behind a structural chassis member, but you’d need to make sure that all other fuel-tank requirements contained in the Fuel Systems chapter (chapter 10) of the NZHCTM could be met, even if the tank would only be used as a return or surge tank.

You’ll find the information on getting steel wheels widened in chapter 12 of the NZHCTM — section 12.10, Steel wheel widening.

Your front axle would need to be strong enough to support the weight of the car. As that this car would be a little heavier than a 1930s-style hot rod, it’d pay to have a local hot rod fabricator — Terry’s Chassis Shoppe, for example — build a custom axle to suit or select an axle that’s designed for this application, rather than hit ‘Buy Now’ on something that may be designed for a lightweight car and therefore would be under spec. The ladder-bar rear suspension, while well proven under lightweight vehicles, has proved problematic in the past when fitted under heavy cars, or in a situation in which there is a lot of suspension travel. There are a number of factors that you’d need to consider before embarking on this part of the build. First, you’d need to read LVV Infosheet No.05-2011: Rear Suspension Radius Rod Geometry.

If done properly, this concept could become a neat street and strip gasser, and it would certainly be a unique addition to the growing fleet of cool old-style cars being built and driven on our roads.

Your thoughts on last month's concept:

- Ross Connelly: Just like ‘KRANKY’, only a two door

- Tony Thorner: The colour would be all I’d change, but that’s just me

- Dean Philpott: Deeper dish on the front wheels. Maybe twin-headlight (Premier) front — just my preference

- Conrad Brownlie: I love Simmons FRs on pretty much anything, so good choice, but don’t like anything bigger than 18s on old-school muscle. Personally, I like Enderle bug catcher scoops, as they sit low and look hard as nails — not a fan of Big and Ugly or shotgun scoops, but that’s just me.

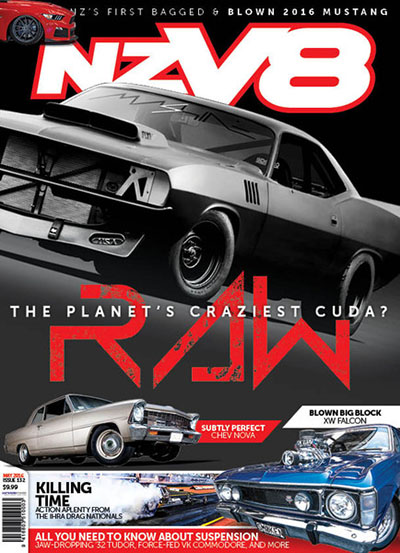

This article originally appeared in NZV8 Issue No. 132. You can pick up a print copy or a digital copy of the magazine below: