Rotary guru Brent Curran of Curran Brothers Racing talks to us about his long-standing relationship with Castrol Edge, the importance of oil in race engines, and what he has learned about lubrication over his racing career.

NZ Performance Car: Hey, Brent. Can you tell us about your first drag car?

Brent Curran: It was a tubbed old-school Mazda 323 running a 240hp [178kW] 13B PP. It ran a best of 12.2[s], if I remember correctly. That engine later went into ‘Mad Mike’ [Whiddett]’s blue Mazda 808 wagon.

Did you build the engine yourself?

Yeah, I built it myself. I was about 23 at the time and working at RX-7 Heaven. My first real drag car that I built was the black Castrol Edge RX-7 with Dan Johnston. It was the first New Zealand 13B to run into the sevens.

What sort of power was that 13B making?

It was running 900hp [671kW] at the wheels and went a best of 7.88[s] at 171mph [275kph].

That car was also sponsored by Castrol Edge, right?

Yeah. We have basically never run any other oil than EDGE; even in my hatch I was running it. It’s lucky really, as I have never had bearing problems, not once out of all my engines. I would often hear about problems with heat and bearings, and be thinking, man, what are you doing wrong? It wasn’t until I saw first-hand a customer’s engine running what is supposed to be a top product that I realized the effects of running the wrong oil.

Here is where the oil does it’s work. These bearings have seen some heavy abuse in the CBR RX-2. 10,000 RPM and mountains of boost.

What viscosity oil do you run in the RX-2?

We run the 25W-50 Castrol EDGE Titanium in everything.

How often do you pull the RX-2’s engine down, and what do you typically find in terms of wear?

We pull the engine down every few meetings just to check things, and we are finding basically no wear. The bearings that are in the four-rotor have been in that motor since we’ve had the four-turbo set-up, and we probably only changed them once — just because we had the engine apart, not because we needed to. We have never wrecked a crank; everything we have used over the years has always gone on into other cars. Even my very first 13B PP I had in the RX-2 ended up in Matt Buttimore’s RX-4, got thrashed in that for a few years, and then the rotors went into his 20B, rusty old things they are. And all the other parts are going into other builds.

A circuit engine like Shaun Judd’s 13B will do an entire season, and we won’t even look at the bearings — it’s a little unreal. I really didn’t know that wasn’t normal, but you would hear of people running bearings and that all the time in circuit cars — people pulling big notes are still having issues with that stuff running other oils. They must just assume [that] if it’s labelled as a racing oil, it’s gotta be good. And you see guys trying to engineer around the problem. But when our customers made the switch, they noticed the difference.

What sort of changes were they seeing?

In one circuit car, it was not getting much heat in the oil. We thought that was a good thing until we pulled it down and you could see that there was too much heat in both the rotors and the bearings. We swapped it to the Edge 25W-50, and, instantly, you could see the oil temperature rise. When we pulled it down, you could see the rotors, bearings, plugs, everything was running much cooler. People go on about high oil temperatures like it’s a bad thing, but it’s not as long as you have an efficient cooling system to remove the heat from the oil. Cooling is a big part of the oil’s job.

Do you Recommend different-viscosity oils for different engines? Say, a methanol turbo 13B and an NA street engine running 98 octane?

No — everything runs the 25W-50 Edge; it doesn’t matter if it’s a methanol, ethanol, or a street rotary running pump gas.

How often should a rotary owner change their oil and filter for street or track use?

In racing applications, a methanol car [should be changed] every couple of meetings, as the oil gets contaminated with methanol — even then, you don’t really need to, but the car sits there for a month, and guys get bored, so they just do it for peace of mind. In a street car, 5000km to 10,000km is fine.

What type of trouble can running the wrong oil in your engine cause?

In a rotary, it’s not so much the oil breaking down but, over time, [that] it becomes contaminated with fuel and carbon, especially in bridgeports, etc.

When does a customer need to think about a dry-sump kit over a factory wet sump?

Pretty much when the oil pump can’t supply the pressure you want. A four-rotor can get away with 90psi on a factory pump, but, as soon as you are pulling 10,000rpm and want 130psi of oil pressure, the factory pump won’t do it. Wet-sump surging is also a factor in both drag cars that 60-foot really good and a circuit car — they will drop oil pressure on some corners.

Rotarys run a premix, with most guys electing to do this in the tank. What oil do you recommend and at what ratio?

We run Castrol R30 in pump fuel, methanol, and E85 applications, at 250ml per 20 litres of methanol and 150ml per 20 litres for pump gases, including E85.

So, guys making the switch to ethanol from pump gas in both street and track cars don’t need to adjust the premix ratio, or run different products?

No, the Castrol R30 is fine. We run 150ml per 20 litres, the same as pump gas. We run clear fuel containers, and we have not seen the R30 separate from the methanol. It’s the same for customers running E85 — their cars will sit for months, and the two don’t separate out; it stays all milky.

What is the purpose of running a premix in rotaries?

It doesn’t just lube the housing; it actually helps seal the motor — you can hear the increase in compression. If you had something running straight petrol, and then you add[ed] 200ml of R30, you [would] … hear the motor liven up a little. I’m not sure why piston guys don’t run it; I guess it’s just habit. I used to stick it into my son’s quad with a worn-out 50cc engine, and, although it would smoke, you could pick the front wheels up.

Thanks for the advice, Brent, and good luck next season with the RX-2’s new engine combination.

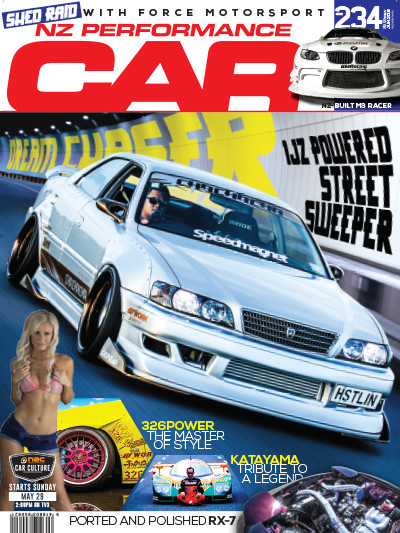

Grab your copy of NZ Performance Car Issue No. 234 below!